Chitosan in Next-Generation Batteries: Sustainable Solutions from Natural Polymers and How Chemical Modifications Unlock Energy Storage Performance

- Entoplast

- 18 minutes ago

- 6 min read

Introduction

The global transition to electric vehicles and renewable energy storage has intensified pressure on battery supply chains whilst simultaneously exposing sustainability vulnerabilities: cobalt and lithium extraction raise ethical concerns, conventional polymer binders like polyvinylidene fluoride (PVDF) derive from petrochemicals, and flammable liquid electrolytes pose safety risks (Subhani et al., 2024).

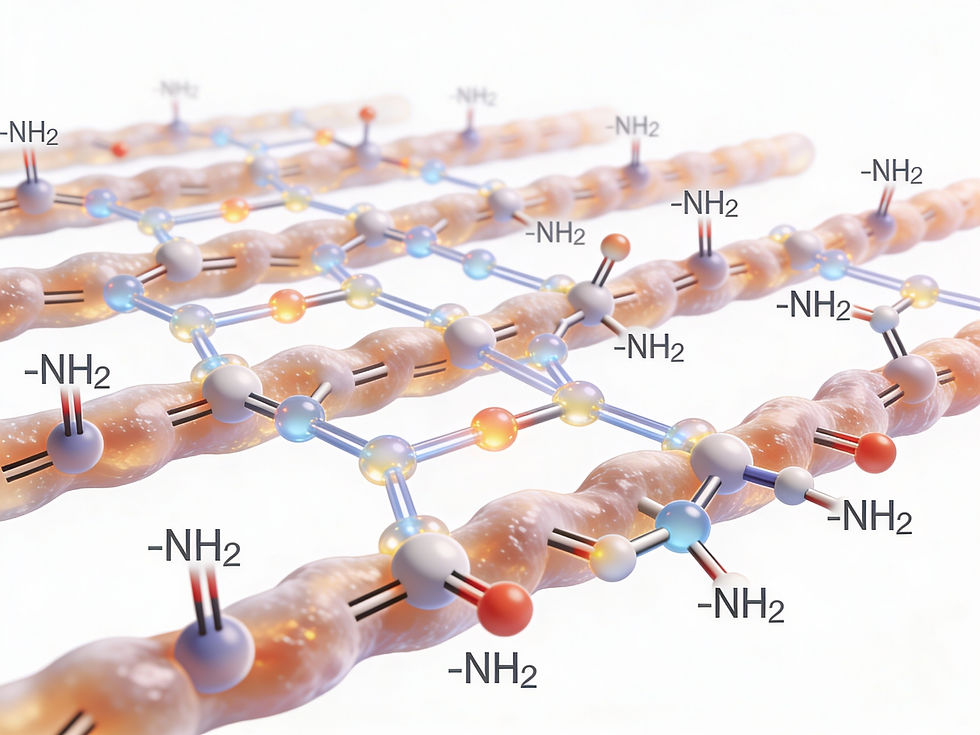

Chitosan (a naturally derived cationic biopolymer obtained through deacetylation of chitin) has emerged as a multifunctional solution across battery architectures. With inherent ionic conductivity via amine and hydroxyl coordination sites, mechanical flexibility for film-forming applications, strong adhesion to electrode materials, and biodegradability, chitosan addresses critical performance and environmental imperatives (Mersmann et al., 2025).

This article examines chitosan's electrochemical properties, recent breakthroughs in electrolyte, binder, and separator applications from 2024–2026 research, chemical modification strategies that unlock commercial-grade performance, and the strategic advantages of Black Soldier Fly (BSF)-derived chitosan in meeting EU Battery Regulation 2023/1542 mandates.

Chitosan's Core Properties for Energy Storage

Chitosan's amine (–NH₂) and hydroxyl (–OH) functional groups coordinate with metal cations (Li⁺, Na⁺, Zn²⁺), enabling baseline ionic conductivities of approximately 10⁻⁶ S/cm in unmodified systems (insufficient for commercial batteries but dramatically enhanced through chemical modifications to exceed 10⁻³ S/cm) (Subhani et al., 2024).

The polymer's film-forming capacity and mechanical flexibility suit solid-state electrolyte and separator fabrication, whilst its superior adhesion to silicon, graphite, and sulphur electrodes arises from hydrogen bonding and chemical cross-linking, outperforming conventional PVDF binders in accommodating volumetric expansion (Chen et al., 2016).

Critically, chitosan is non-flammable, eliminating thermal runaway risks associated with organic liquid electrolytes, and biodegrades within months, contrasting with petrochemical polymers that persist for centuries. Recent 2025 studies demonstrate chitosan-based poly(ionic liquid) additives regulate zinc chemistry in aqueous systems through multi-anion–cation interactions, achieving 5,925 hours of cycling stability (a breakthrough for stationary storage) (RSC Energy & Environmental Science, 2025).

Applications: Electrolytes, Binders, and Separators

Solid and Gel Polymer Electrolytes

Chitosan-based solid and gel polymer electrolytes (SPEs and GPEs) combine safety with competitive ionic transport. In lithium-ion systems, chitosan-LiTFSI electrolytes incorporating 15 wt% Al₂O₃ nanofillers achieve room-temperature ionic conductivities of 3.38 × 10⁻⁴ S/cm, with values rising to 5 × 10⁻³ S/cm at elevated temperatures (approaching liquid electrolyte performance whilst maintaining solid-state safety) (Subhani et al., 2024).

Sodium-ion batteries benefit from chitosan-cellulose acetate nanocomposite electrolytes, reported in 2025 symposiums to deliver stable cycling in prototype cells (IOP Science, 2025).

For aqueous zinc batteries, chitosan-based poly(aprotic/protic ionic liquid) additives regulate Zn²⁺ solvation structures via carboxylate and chloride anions, achieving ultra-high cumulative plating capacities exceeding 7,550 mAh/cm² at 10 mA/cm² current density (critical for grid-scale deployment) (RSC Energy & Environmental Science, 2025).

Binders for High-Capacity Anodes and Cathodes

Silicon anodes promise 10× the capacity of graphite but suffer catastrophic pulverisation during lithiation. Cross-linked chitosan binders form 3D networks through glutaraldehyde linkages, anchoring silicon particles and accommodating 300% volume expansion; 2024–2025 studies report 80%+ capacity retention after 500 cycles at 1C rates, compared to <50% for PVDF controls (Chen et al., 2016; Subhani et al., 2024).

Self-healable chitosan binders incorporating dynamic covalent bonds further extend cycle life beyond 1,000 cycles in recent 2026 demonstrations (Chemical Engineering Journal, 2026).

For lithium-sulphur batteries, chitosan's amine groups trap polysulphide intermediates through Lewis acid-base interactions, mitigating shuttle effects; studies show chitosan-reduced graphene oxide composite binders enable 600+ cycles with <0.05% capacity fade per cycle (Electrochimica Acta, 2024).

Importantly, water-based chitosan processing eliminates toxic N-methyl-2-pyrrolidone (NMP) solvents, reducing manufacturing costs by 15–20% and meeting green chemistry standards.

Separators and Dendrite Suppression

Chitosan-cellulose and chitosan-ceramic hybrid separators combine biodegradability with high ionic conductivity and thermal stability. A 2025 Nature Communications study reported anisotropic chitosan-nanofibrillated cellulose separators produced via directional freezing suppress zinc dendrite formation through aligned ion channels, enabling 2,000+ hours of symmetric cell cycling at 2 mA/cm² (Nature Communications, 2025).

Chitosan's hydrophilicity enhances electrolyte wettability, reducing interfacial resistance by 40% compared to polyolefin separators, whilst maintaining thermal shutdown capability above 150°C (a critical safety feature absent in conventional membranes).

Chemical Modifications Unlocking Performance

Cross-Linking for Mechanical Integrity

Cross-linking agents (glutaraldehyde, genipin, citric acid) react with chitosan's amine groups to form covalent networks, enhancing mechanical strength from ~0.3 MPa to >3 MPa whilst maintaining ionic conductivity (Subhani et al., 2024).

Glutaraldehyde cross-linking optimised at 1–2 wt% balances conductivity and strength; excessive cross-linking (>5 wt%) restricts polymer chain mobility, reducing Li⁺ transport by 30–40%.

Recent 2024 work demonstrates genipin, a biocompatible alternative, achieves equivalent mechanical performance without cytotoxicity, facilitating bio-integrated battery applications.

Grafting with PEG/PEO Chains

Grafting polyethylene glycol (PEG) or polyethylene oxide (PEO) onto chitosan backbones dramatically enhances ionic conductivity. PEGylated chitosan, synthesised via nucleophilic substitution, exhibits room-temperature ionic conductivities of 1.12 × 10⁻³ S/cm (10× higher than unmodified chitosan) with Li⁺ transference numbers of 0.816 (Polymers, 2022).

The ether oxygen atoms in PEG/PEO segments coordinate Li⁺ ions, facilitating segmental motion, whilst chitosan's rigidity provides dimensional stability. A 2025 study reported chitosan-g-PEO electrolytes achieving 5 × 10⁻³ S/cm at 60°C, enabling LiFePO₄ full cells to deliver 160 mAh/g over 200 cycles at 0.5C.

Nanocomposite Formation

Incorporating nanomaterials creates synergistic enhancements. Chitosan-graphene oxide (GO) composites leverage GO's high surface area and electrical conductivity; 2025 research demonstrates 5 wt% GO loading increases ionic conductivity to 5.2 × 10⁻³ S/cm at 25°C through disrupting chitosan crystallinity and providing conductive pathways (Subhani et al., 2024).

Metal-organic framework (MOF) fillers, particularly zeolitic imidazolate framework-8 (ZIF-8), enhance Li⁺ transference numbers from 0.18 to 0.36 by adsorbing anions via Lewis acid-base interactions; cells retain 85% capacity after 350 cycles at 0.2C (Subhani et al., 2024).

Chitosan-clay (montmorillonite) nanocomposites achieve ionic conductivities of 2.28 × 10⁻⁴ S/cm with flame retardancy and mechanical strength of 12.58 MPa (ideal for automotive applications) (Subhani et al., 2024).

Performance Benchmarks from 2024–2026

Recent literature establishes chitosan's competitive position:

Ionic Conductivity: Modified chitosan electrolytes: 3–5 × 10⁻³ S/cm at 25°C; 10⁻² S/cm at 60°C (comparable to PEO-based SPEs).

Cycle Life: Silicon anodes with chitosan binders: 80–90% capacity retention after 500 cycles; lithium-sulphur cells: >600 cycles with <0.05%/cycle fade.

Mechanical Strength: Cross-linked chitosan films: 3.6 MPa tensile strength, 900% elongation at break.

Safety: Non-flammable; thermal stability to 200°C; no dendrite-induced short circuits in 2,000+ hour symmetric cell tests.

Comparison: Chitosan matches PVDF in adhesion, exceeds it in volumetric accommodation (3× for silicon), and eliminates NMP solvent toxicity. Versus liquid electrolytes, chitosan sacrifices ~20% conductivity but gains solid-state safety and eliminates leakage risks.

Sustainability and BSF Sourcing

Life-Cycle and Regulatory Alignment

Preliminary life-cycle assessments indicate chitosan-based batteries exhibit 40–60% lower carbon footprints than PVDF equivalents, primarily through avoided petrochemical synthesis and water-based processing.

The EU Battery Regulation (2023/1542), effective February 2024, mandates carbon footprint declarations, recycled content thresholds (escalating to 16% for cobalt by 2031), and due diligence on supply chains (EU Official Journal, 2023). Chitosan derived from renewable biomass satisfies sustainability criteria, whilst biodegradability addresses end-of-life concerns (critical as Europe targets 1 million tonnes of spent batteries annually by 2030).

The US Inflation Reduction Act (IRA) incentivises domestic battery material sourcing; BSF farming infrastructure scales rapidly, with 400% growth in European capacity since 2020 supporting localised chitosan supply (Mersmann et al., 2025).

BSF-Derived Chitosan Advantages

Black Soldier Fly larvae, reared on organic waste streams, yield 7–10% chitin by dry mass, with pupal exuviae containing up to 25.5% chitin at 86.8% purity post-bleaching (comparable to crustacean-derived standards) (Mersmann et al., 2025).

BSF chitosan offers:

(1) Circular Production: waste valorisation eliminates marine resource pressure, critical as crustacean stocks decline;

(2) Traceability: controlled farming ensures consistent molecular weight (26–300 kDa) and deacetylation degree (70–90%), reducing batch variability that plagues marine sources;

(3) Cost Competitiveness: waste-fed BSF reduce production costs

Extraction via green solvents further enhances sustainability profiles (Mersmann et al., 2025).

Conclusion

Chitosan has transitioned from academic curiosity to commercially viable battery material, validated by 2024–2026 breakthroughs demonstrating >10⁻³ S/cm ionic conductivities, 500+ cycle lifespans in silicon anodes, and dendrite-free zinc plating exceeding 7,000 mAh/cm².

Chemical modifications (cross-linking, PEG grafting, nanocomposite formation) unlock performance rivalling synthetic polymers whilst retaining biodegradability and water-processability.

Market timing aligns with regulatory drivers: EU Battery Regulation 2023/1542 mandates sustainability transparency, and US IRA incentivises domestic supply chains. BSF-derived chitosan, leveraging circular bioeconomy principles and European farming infrastructure scaling to 1 million tonnes by 2030, positions chitosan as the strategic biopolymer for next-generation batteries.

Entoplast, with specialist expertise in high-purity BSF chitosan production, offers battery researchers and R&D teams a traceable, cost-competitive feedstock. Contact Entoplast to discuss sample specifications and co-development for your next-generation battery project.

Comments